The White Rust Problem in Galvanized Tower Systems

The use of galvanized steel in small-to-medium-sized cooling towers is still very common today, despite the prevailing incidence of premature deterioration of the galvanized components due to white rust. Premature failure means that the tower is not able to reach its intended service life, and in some extreme instances cooling towers are replaced after only a year or two of service. The cost effectiveness of galvanized steel has been the main reason why the use of alternative corrosion resistant materials such as stainless steel, plastic or fiberglass has not gained full momentum.

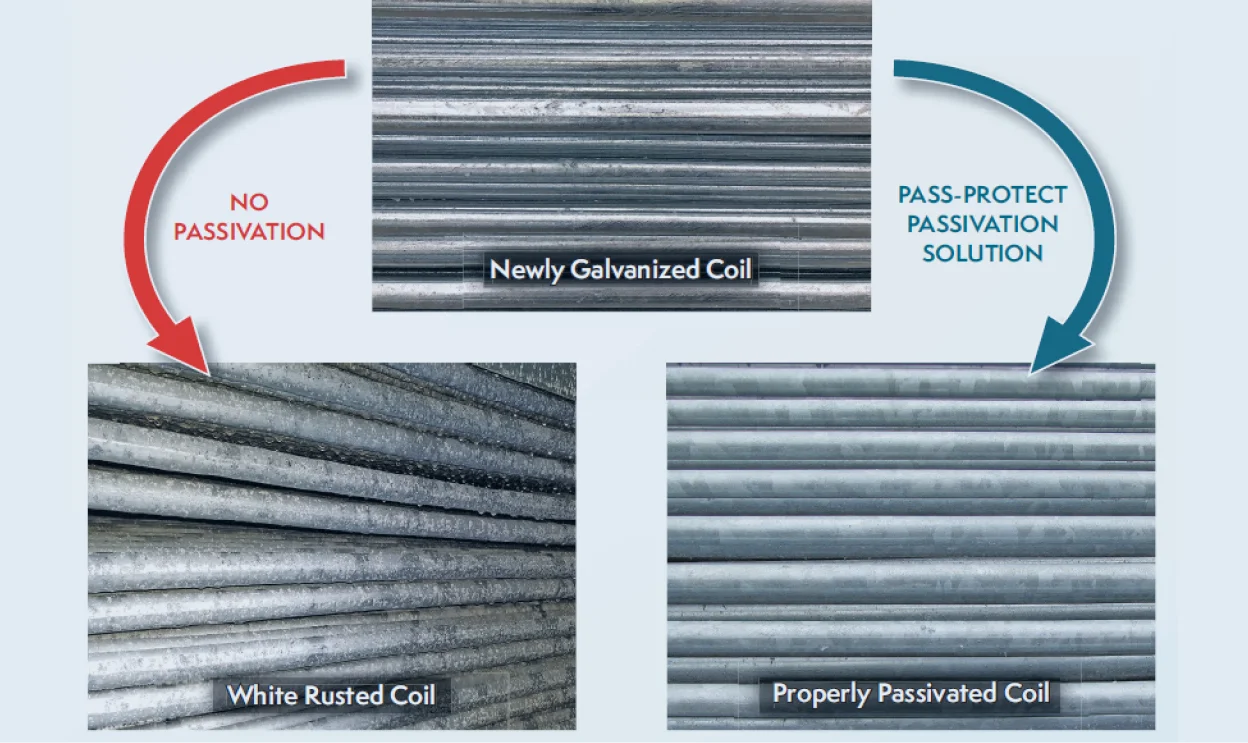

Solution: Passivation is key to establish protection:

Passivation plays a critical role in white rust prevention. Our HNW passivation program is recommended as the appropriate pretreatment in establishing protection, especially for new cooling towers. Passivation is also recommended whenever there are signs of white rust after a cleaning, high doses of oxidants, turn around or shutdown periods.

Chemistry control is Chemistry control is important:

- Control of pH and calcium hardness is very important in controlling white rust

- Control the pH near neutral (between 7 – 8)

- Control calcium hardness levels to > 50 ppm as CaCO3

- Keep chloride content (as Cl– ) below 450 ppm

- Keep sulfate content (as SO4 –2) below 1200 ppm

- Control bicarbonate alkalinity (as CaCO3 ) below 300 ppm