Running RO Plants the Right Way

Why RO Plant Performance Matters to Your Bottom Line

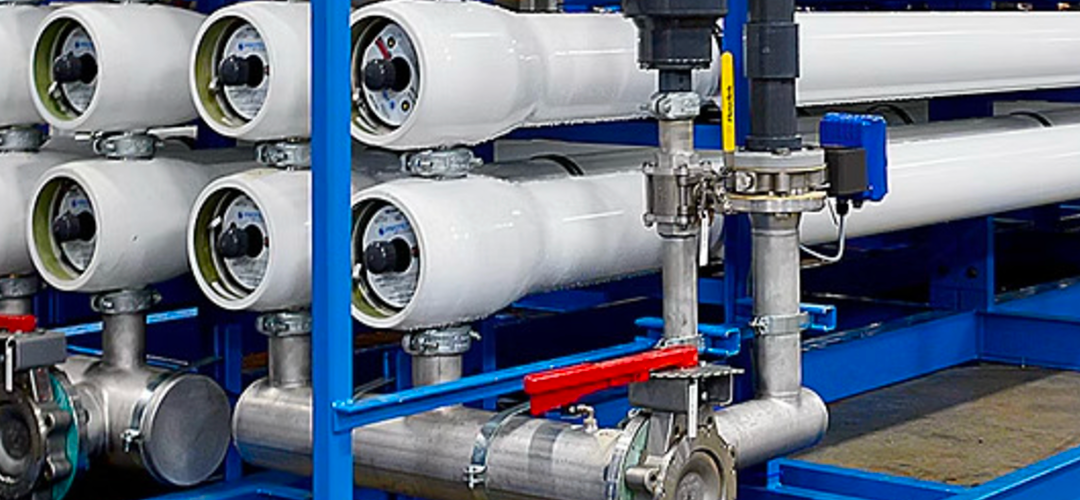

However, RO systems are inherently sensitive equipment. Even small variations in water quality or operating conditions can trigger membrane fouling, scaling deposits, or pump failures. The result is expensive unplanned downtime, process disruption across your facility, and premature capital expenditure on replacement equipment.

The good news: With disciplined operation, robust water treatment protocols, and real-time visibility into system performance, RO plants can run reliably for years with predictable, consistent performance that protects your operational continuity.

10-15%

Typical DP Rise

10-15%

Typical DP Rise

Strong Pre-Treatment: Your First Line of Defense

In industrial and commercial operations, incoming water quality can vary dramatically on a daily basis municipal supply changes, borewell

fluctuations, seasonal shifts, construction dust contamination, or pipeline corrosion. If your pre-treatment system is not robust and properly

maintained, your expensive RO membranes will foul rapidly, leading to performance degradation and costly replacements.

Multi-Media Filters (MMF)

Activated Carbon Filters (ACF)

Softener or Antiscalant

Cartridge Filters (1-5µ)

Iron & Manganese Control

Monitor Critical RO Parameters Daily

Feed TDS & Conductivity

Differential Pressure (DP)

Permeate Flow Rate

Permeate Conductivity

Recovery Rate

Implement a Scheduled CIP Program

Feed TDS & Conductivity

- Permeate flow drops 10-15% from baseline

- Differential pressure increases by 15% or more

- Conductivity rises beyond acceptable limits

- Pre-filter replacements become unusually frequent

Fouling Types Addressed

- Scaling: Calcium, magnesium, silica deposits

- Organic fouling: Food, pharma, beverage operations

- Metal fouling: Manufacturing and utilities

- Microbial fouling: Hotels, hospitals, QSR spaces with storage tanks

Critical Operating Limits: Recovery, Chlorine, and Pressure

Avoid High-Recovery Operation

Ensure Zero Chlorine Leakage

Protect from Pressure Shocks

Hygiene and System Cleanliness

Regular Disinfection

Cartridge Replacement

Dosing Line Maintenance

Biofilm Inspection

Tank Integrity

Real-Time Monitoring for Predictive Maintenance

Trend Analysis

Chemical Dosing

Smart Alerts

Performance Scoring

Operator Training and Preventive Maintenance

Train Operators Properly

Structured Maintenance Plans

Industrial RO systems require:

- Mechanical pump inspection and lubrication schedules

- Flow meter calibration and validation

- Membrane integrity testing protocols

- Antiscalant demand analysis

- Quarterly comprehensive system audits

Commercial RO systems require:

- Frequent cartridge replacements

- Regular sanitization cycles

- Storage tank inspection

- UV lamp maintenance and replacement

Building Resilient, Long-Lasting RO Operations

Cost Reduction

Extended Life

Uptime Improvement

Industrial and commercial RO plants achieve maximum asset life when they are protected with robust pre-treatment systems, operated within

design parameters, cleaned at optimal intervals based on performance data, safeguarded from chlorine exposure, pressure shocks, and voltage

fluctuations, monitored continuously through real-time data analytics, operated by properly trained personnel, and supported with structured

preventive and predictive maintenance programs.

By following these proven practices, facilities can significantly extend membrane and pump life, reduce operating costs, avoid unexpected

breakdowns, and minimize capital expenditure on premature replacements.

With HNW’s RO treatment chemistry, engineered systems, and Smart Plant monitoring platform, industrial and commercial operations don’t

just run RO plants they run efficient, resilient, and long-lasting water treatment systems that protect operations and deliver consistent water

quality.